Choosing the right screen material

Matching material color and finish to the environment helps determine image quality. Every screen material has specific characteristics suitable for different viewing environments and applications. A simple matte white screen is likely your best option if you are presenting a large display in a darkened room. Not only is this a cost-effective solution, but the material provides even light distribution so that viewers seated at any angle can see the image properly.

Here is a simple breakdown of the most common screen materials available on the market:

Gain screens: Gain screens are coated with specially formulated coatings developed specifically for their optical characteristics. They can be white or silver. Silver screens use aluminum flakes that are used to strategically disperse light back to the audience and are a must for polarized 3D. Gain screens are primarily used in controlled cinema environments where limited viewing angles aren’t an encumbrance. They can also be used to augment brightness when projectors have insufficient light output and can reduce the demand of light output, preserving expensive projector lamps.

White screens: A perfectly matte white screen has a gain of 1.0 and a flat gain curve, meaning that light is evenly distributed across the surface and that the image will be equally as bright no matter where an audience member is seated. Matte white screens are chosen for their light dispersion qualities, wide viewing angles, and lower cost.

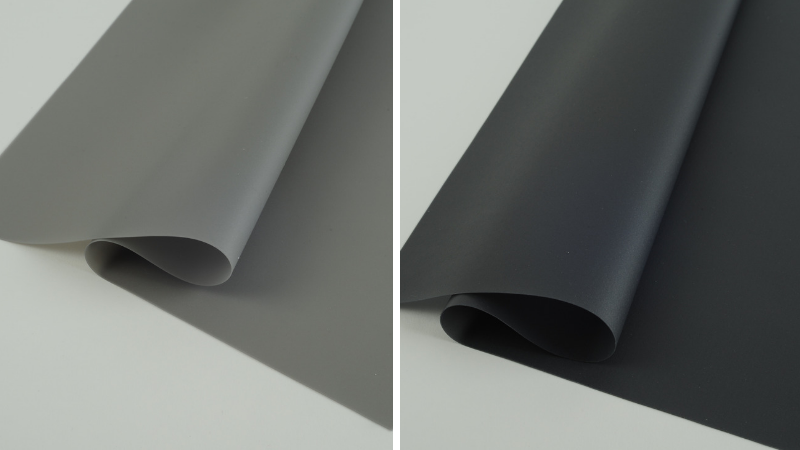

Grey screens: While all surfaces reduce contrast, darker screens have the advantage of higher contrast ratios because they reflect and diffuse deeper levels of black. For more powerful projectors, the use of gray and black screens is recommended. Because powerful projectors provide enough light output to offset the effects of a darker screen, the screen can be used to preserve contrast levels and provide deeper color saturation.

Grey screens are also used in rooms with high ambient light. However, more than just screen color, you should look for screens made specifically for these conditions. These screens are commonly known as ambient light rejecting (ALR) screens. In truth, ALR screens don’t actually reject ambient light, they are designed to both absorb it and redirect it away from the viewer. While white screens diffuse light uniformly across the entire surface, ambient light rejecting surfaces, are designed to redirect off-axis light (light other than that emitting from the projector) away from the viewer’s field of vision. The structure of the surface also absorbs indirect light.

Black screens: Black screens have optimal contrast levels due to their ability to reflect black levels perfectly. These screens perform best in environments with high ambient light and should be used in conjunction with powerful projectors that provide high lumen output. Black translucent screens can be used for both front or rear applications.

Other screen materials are available for specific purposes. For instance, translucent off-white surfaces can be used for both front and rear projection simultaneously. Some materials are offered with black backing to absorb intrusive background light, such as light coming from windows.

To meet growing consumer demand, the gamut of screens available on the market is increasing. This makes understanding the factors that determine screen choice all the more important. Your screen manufacturer should be able to provide the best surface option based on the following main determining factors:

- Light output and resolution of your projector

- Projector lens

- The amount of ambient light in your room

- The size of the screen (s) that you want to use

- Speaker placement

- Audience placement and room size